Technical Welding Supply LLC

Our Foundation

Technical Welding Supply was founded on the principle of filling an industry need with welding supplies and industrial gases. Operating within the greater San Francisco Bay Area, we are in a market saturated with large publicly held conglomerates and few competitive local family owned companies.

Who we are?

Here exists a great need for an independently owned and operated welding supply catering to our customers success, instead of loyalties to share holders. Over the decades of industry experience, our family has realized that customers of all sizes need superior Industry support for success.

How can we help?

Sharing our welding and industry experiences personally not only in the Welding industry, but additional industries as well, will benefit our customer base greatly! We enjoy our customers! Please contact us and see how a personal approach can be of benefit to you!

Photo Gallery one-(still under construction)

.jpg/:/cr=t:0%25,l:0%25,w:100%25,h:100%25/rs=w:370,cg:true)

Photo Gallery two-(still under construction)

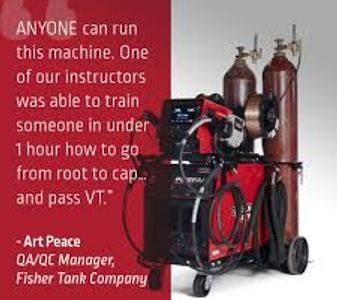

Advanced Welding Equipment from Lincoln Electric

New Pipefab from Lincoln Electric

The Ideal Setup for Pipe & Vessel Fabrication From concept to reality, the PIPEFAB™ welding system was developed for one purpose – to deliver the ideal setup for pipe and vessel fabrication. From machine design to arc performance, no detail was overlooked in delivering a complete, customer-driven system that lets your shop focus on what matters most – making high-quality root-to-cap welds, faster and easier.

https://www.youtube.com/watch?v=9jT7oTPIRRg

https://lincolnelectric.com/assets/global/Products/K3734-1/e513.pdf

Powerwave family of welding platforms by Lincoln Electric

The multi-process Power Wave® S500 is packed with Lincoln Electric performance technology for welding on thicker materials. It provides an extremely fast arc response, includes over 65 standard welding waveforms for optimized performance on almost any application and efficiently converts input power to reduce operational costs

https://www.lincolnelectric.com/assets/global/Products/K2904-1/e5115.pdf

https://www.youtube.com/watch?v=_iaYOXDAYTI

Advanced Welding Equipment from Miller Electric

New Dynasty 400 TIG from Miller Electric

Latest technology - powerful, compact AC/DC inverter delivers superior arc performance with total AC arc-shaping capabilities. Auto-Line™ allows connection to any voltage or frequency in the world while using half the power of a conventional machine.

https://www.youtube.com/watch?v=5KgG2NRFYWc

Continuum™ 350 907636New generation of advanced industrial welding solutions improves productivity through weld quality, ease of use and system flexibility.

The Continuum system delivers exceptional arc performance with less spatter and higher-quality welds on both thin and thick metals. With user-friendly controls and system modularity, Continuum will make challenging jobs easier, and improve productivity — giving you a competitive advantage.

https://www.youtube.com/watch?v=LPKv7eIIND0

https://www.millerwelds.com/-/media/miller-electric/imported-mam-assets/spec-sheets/6/c/8/dc36-0.pdf

Oxy-Fuel Equipment from Miller and Victor -(still under cons

Miller Oxy-Fuel Equipment

Oxy fuel welding, also known as gas welding or oxyacetylene welding, is a process that uses oxygen and gases such as acetylene, propylene, or propane, to weld and cut metal. Miller offers gas equipment to completely outfit your oxy fuel needs – including outfits, regulators, torches, tips and gas mixers.

https://www.millerwelds.com/equipment/gas-equipment

TORCH SAFETY TRAINING BY MILLER!

https://www.youtube.com/watch?v=Bcx4Qbp2BK0

** WE ALSO OFFER FREE TORCH SAFETY CLASSES FOR OUR CUSTOMERS. PLEASE CALL OR E-MAIL US FOR MORE INFORMATION **

Victor's tradition of unparalleled safety, performance and reliability remains a cornerstone of the brand.

https://www.esabna.com/us/en/products/brands/victor/index.cfm

TORCH SAFETY TRAINING BY VICTOR!

https://www.youtube.com/watch?v=3_C_kFil93E

** WE ALSO OFFER FREE TORCH SAFETY CLASSES FOR OUR CUSTOMERS. PLEASE CALL OR E-MAIL US FOR MORE INFORMATION **

Welding Advice from the experts

MIG welding advice from Lincoln Electric

About Us

Welding Supplies and Filler Metals

Welding Supplies and Filler Metals

Welding Supplies and Filler Metals

We support products and filler metals from Miller, Lincoln, Hobart, Tweco, Victor, Inweld, Washington Alloy and many more. We have product knowledge above and beyond most of our competitors. We enjoy our customers and also enjoy making them more profitable at the same time.

Retail Locations

Welding Supplies and Filler Metals

Welding Supplies and Filler Metals

Currently we are only operating out of a warehouse but do have plans to start opening retail stores in the second quarter of 2021. Covid-19 has complicated all of our business plans in one way or another and we consider the health and safety of our customers as top priority. Please check back with us for future plans!

Watch our growth!

Welding Supplies and Filler Metals

Watch our growth!

As a start up, we can offer a wide spread line of welding supplies as well as a micro bulk offering. Plans for first and second quarter 2021 will also include packaged gas and cryogenic Dewar offering that will include 500 PSI Dewars. While Covid-19 has slowed business down for us all, we are looking forward to a good time when the effects of Covid-19 will be minimal or eliminated!

Contact Us

Better yet, see us in person!

We have a passion for our industry and enjoy our customers. Feel free to call or E-mail us for a visit. Please call us at (669)274-5629 E-Mail at technicalweldingsupply@gmail.com

Technical Welding Supply

Copyright © 2024 Technical welding - All Rights Reserved.

Powered by GoDaddy